A test flight yesterday by a Boeing 787 Dreamliner began what the company hopes will be the final steps toward getting the green light to put the airplane back in the air. FAA approval of extensive changes to the airplane’s two lithium-ion battery packs would not mean that passengers will be boarding 787s immediately—it will take many weeks to retrofit the fleet of 60 or more airplanes already delivered to airlines, and even longer for the airlines to re-integrate the jets into their schedules. But for Boeing, it will be the beginning of the road back from the worst blow ever to its reputation.

But hold the applause.

First, the 787 will fly again without anyone—Boeing, the Federal Aviation Administration, or the National Transportation Safety Board—being sure of exactly what caused the battery failures that grounded the fleet in the first place.

Second—and this is all too easily overlooked in the barrage of reassurances being issued by Boeing—the measures being taken to make the batteries safe are in themselves an indictment of the way the technology was adopted.

Back in 2007, when the FAA first reviewed the proposed battery system, according to a notice published by them, they realized that the current airworthiness regulations “did not contain adequate or appropriate safety standards” for lithium-ion technology, which had “certain failure, operational and maintenance characteristics that differ significantly from those of the nickel-cadmium batteries currently approved for large transport category airplanes.”

They cautioned that “other users in other industries have noted safety problems including overcharging, over-discharging and flammability” and that “these batteries are significantly more susceptible to internal failures that can result in self-sustaining increases in temperature and pressure (thermal runaway).” And they warned that because of the size of battery that Boeing was proposing there was a greater risk of overcharging which could lead to an external fire.

Boeing has admitted that, even following those warnings, the tests carried out by them and the FAA during the certification process did not result in sufficient safeguards against failure. The chief project engineer for the 787, Mike Sinnett, said at a press briefing on March 15 in Tokyo that the safety standards now used for the new battery installations “weren’t available when we set the testing plan for the baseline battery.”

Who set those new standards? Surprisingly, not the FAA or Boeing. They were developed by a little-known body with the quaint name of the Radio Technical Commission for Aeronautics, or RTCA, a nonprofit authorized to give technical guidance to government regulators.

As they scrambled to get a grip on the battery crisis Boeing built a “brain farm” of experts from academia, aerospace, national laboratories and other industries. No fewer than 500 engineers spent more than 200,000 hours testing sets of batteries and trying, without success, to reproduce the failures that grounded the 787—the first on January 7 in a Japan Airlines 787 parked at the gate in Boston and the second a week later while an All Nippon Airways 787 was in the air over Japan.

Why exactly did Boeing risk using a battery technology that had never been exposed to the punishing demands of airline operations and which was known to be prone to overheating and catching fire?

In Tokyo, Sinnett put it simply: “Lithium-ion earned its way on to the airplane.”

The 787’s designers set tough targets for themselves. Boeing promised airlines whose profits were being destroyed by rising fuel costs that the airplane would guzzle 20 percent less gas than the airplane it replaced, the 767. A chunk of that improvement came directly from a new generation of engines that are at least 15 percent more fuel efficient. The rest had to come from the airplane, and the best way to achieve that was to make the structure lighter. For the first time Boeing replaced metal with composites for 50 percent of the airplane, cutting weight substantially. The batteries were a relatively tiny part of this calculation, but every ounce counted, and lithium-ion batteries delivered far more power for their weight than the traditional nickel-cadmium batteries. They were also cheaper to maintain because they kept their charge better than nicad batteries, which lost charge when stored.

In fact, these batteries were a crucial part of what Boeing called the “more electric” airplane, a change that itself promised to lower fuel burn by up to 3 percent.

Like other close observers of the 787’s battery crisis, I’ve wondered why, when the seriousness of the problem became clear, Boeing didn’t have a Plan B—to revert to the nicad batteries which had a long history of reliability. When Airbus, having seen the 787’s battery problems, announced that it was reverting to nicad batteries for its challenger to the 787, the A350, they said the difference in weight was equal only to the weight of about one passenger. Was Boeing just doubling down for the sake of not losing face?

Then I realized they had no choice. The architecture of the “more electric” airplane had been made dependent on the unique nature of power drawn from the lithium-ion batteries. The clue came in a lengthy briefing Sinnett gave in January, on the heels of the battery emergency in Boston.

That emergency involved the battery used to start the small jet engine in the tail of the 787 (common to all jets) called the Auxiliary Power Unit, which provides power to systems when the main engines are shut down on the ground. Sinnett explained that the lithium-ion battery was ideal for “a high energy task like an APU start” and he added: “Lithium-ion technology is really the only practical battery application that allows us to do that.”

In other words, you couldn’t introduce nicad batteries without having to change the entire architecture of the electrical system, something that would end up costing huge sums.

By the time Sinnett appeared in Tokyo, alongside Ray Conner, the president and CEO of Boeing Commercial Airplanes, he displayed an aggressive new confidence in the choice of battery. When Boeing chose the technology it was, he said, “already mature” and he cited its use in aerospace, on satellites and on rockets. (None of which demands the kind of everyday flawless performance we expect of an airliner).

But he went further. The seriousness of the Boston episode had been exaggerated. “There was no fire at all,” he said.

This was pretty startling. The NTSB published a detailed account of the incident on February 12. One of the first mechanics to reach the airplane reported seeing a flame, about 3 inches long, around the battery case. A firefighter using a thermal imaging camera saw a white glow “the size of a softball.” A firefighter using shots of a chemical called Halotron reported that “the fire would knock down and flare back up when hit with multiple shots.”

Then there was the issue of smoke. Sinnett said there wasn’t any smoke. It was “vaporized electrolyte which looks like smoke but is not the result of combustion.”

This argument would have seemed academic to the Japan Airlines station manager who, responding to an emergency call, boarded the 787 at the gate and found intense and caustic-smelling smoke billowing up through the cabin floor from the electronics bay below. It would also have seemed academic to the firefighter whose neck was burned when the battery case exploded.

(A year earlier, the firefighters at Boston had been guided in how to tackle a fire on the 787 by a Boeing Power Point presentation. Months later, when they encountered a 787 for the first time, they discovered that the batteries were not where the presentation had put them—their diagrams had to be corrected.)

Sinnett insisted that there had not been a fire inside the battery casing. But the heat from the thermal runaway was intense enough to melt the cells of the battery and the vaporized electrolyte, call it what you will, was toxic and invasive and the battery was, according to the firefighters, still “off-gassing” when it was removed 80 minutes after the emergency began.

The NTSB is not happy that, with their own investigation continuing, Boeing “provided their own analysis and conclusions” on the Boston incident. Peter Knudson, an NTSB spokesman, told me: “The NTSB has not ruled out a fire in the battery box.”

In the absence of a known cause for the battery failures the fixes now being presented to the FAA to get the 787 back in the air look like a “catch all” remedy.

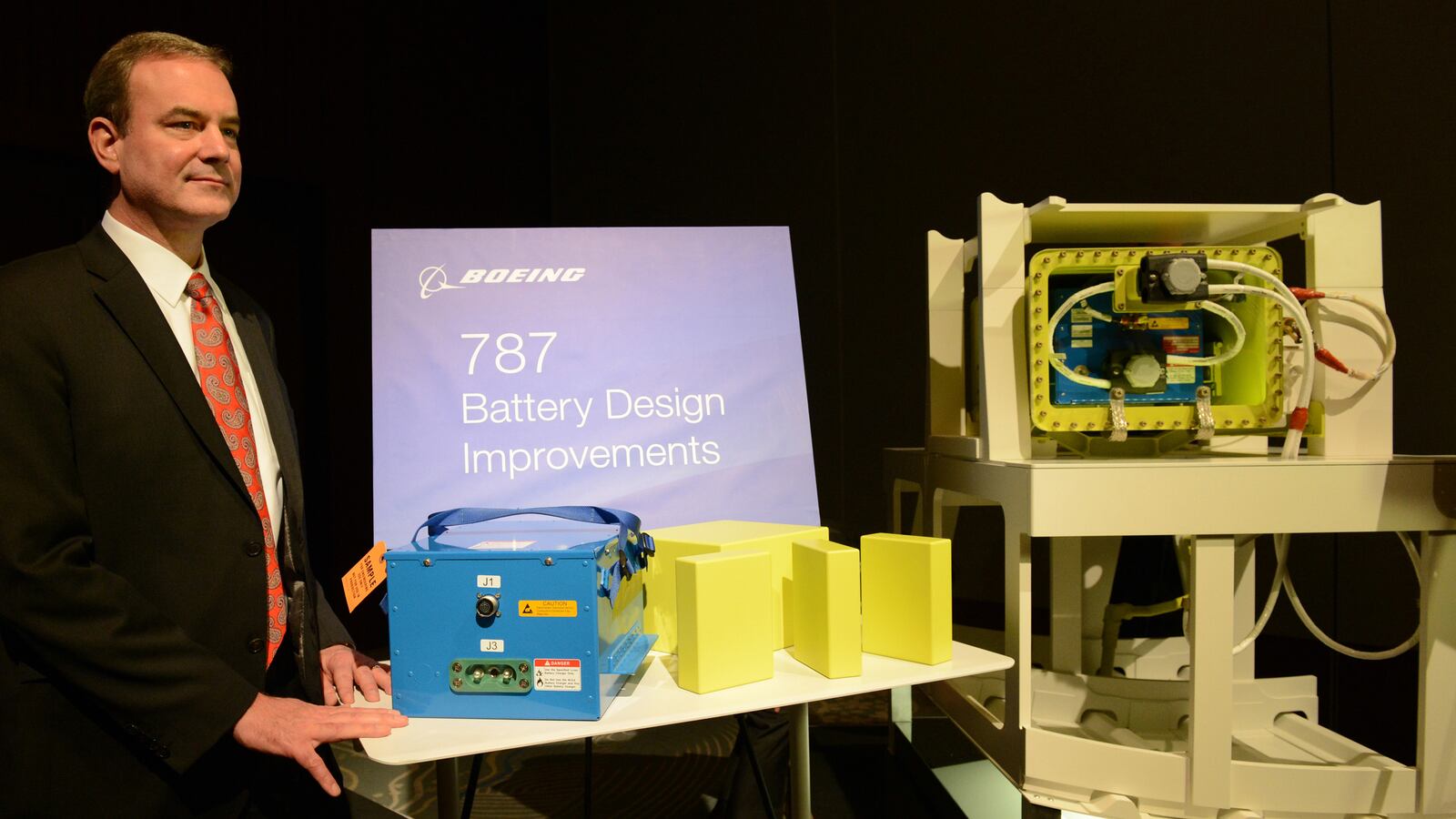

The batteries are now enclosed in a stainless steel box. If combustion occurs within a battery, says Boeing, it would be snuffed out in a microsecond for lack of oxygen. The “vaporized electrolyte” would be vented through a new system directly “overboard” through tubes that exit through the belly of the airplane.

Note the careful language of CEO Conner, announcing the changes (italics mine): “We have proposed a comprehensive set of solutions designed to significantly minimize the potential of battery failure…In the unlikely event of battery failure, the new enclosure system will keep any level of battery overheating from affecting the airplane or being noticed by passengers…”

Starting a fire requires two things: Ignition and combustion. Boeing claims to have eliminated the risk of combustion, but not ignition. Lori Gunter, a Boeing spokesperson, told me: “The battery and enclosure system have been designed to minimize sources of ignition…the venting of the cells would force the very small amount of oxygen in the enclosure out the vent line. With the absence of oxygen, there is no possibility of fire regardless of if the airplane is in flight or on the ground.”

It is as well to remember that by allowing the 787 back in the air the regulators are prepared to tolerate the presence on an airliner of a system that needed such belt-and-suspenders protection—certainly robust but far from elegant. Bear in mind, too, that another battery failure could happen when the airplane is far from an emergency runway—the ANA flight was over land and the pilots were able to be on the ground within 16 minutes of being alerted to the problem.

There is no doubting that, as they say, Boeing’s engineers and executives are committed to safety as their first priority and that they believe that the 787 will prove to be one of the safest airplanes in the sky. Even so, these are the same people whose hubris led to the fiasco in the first place.