An international team of engineers have taken 3D printing to a whole new level by designing a fleet of drones that can build structures while in flight, unlocking new approaches to construction in hard-to-reach, unstable, or otherwise inaccessible places. These robots are the first of their kind to 3D print and hover simultaneously, and in proof-of-concept research published on Wednesday in Nature, researchers showed that the drones were able to coordinate and build tall cylinders out of polyurethane foam and a cement-like material.

“We've demonstrated the first-ever robots that are 3D-printing in flight, and it's a pretty amazing achievement,” Robert Stuart-Smith, an autonomous manufacturing researcher at University College London and the University of Pennsylvania, and a co-author of the study, told The Daily Beast. By working with swarms of small robots that can make decisions as they build, tomorrow’s architects will be able to change building designs halfway through construction and tailor projects to fit a dynamic environment, he added.

The potential implications are myriad. The new drones could provide new opportunities to construct buildings outside of the formulaic one-floor-after-another approach. Or, after a natural disaster like an avalanche, drones could 3D print tools for an entrapped survivor to free themselves. They might also be able to quickly construct temporary shelters for displaced individuals and families. Since they are free-roaming and don’t need to be plugged in, 3D-printing drones could assist when there’s a power outage from a storm or other weather event, making quick repairs to vital infrastructure (especially if there are obstacles preventing humans from getting close).

Taking inspiration from insects like bees and wasps, as well as recent research into teams of mobile robots that can self-organize, Stuart-Smith, who co-led the study with Mirko Kovac, and his other colleagues wanted to build a system of 3D-printing drones that could build in locations that traditional—and even state-of-the-art 3D-printed construction technologies—can’t reach. So-called additive manufacturing is currently limited by the size of its equipment; 3D-printed structures can’t be wider than the printer’s base, and printers must maneuver around layers they have already deposited, creating time-consuming situations. By contrast, a flying 3D printer can deposit material below itself and move anywhere in space, allowing for structures with unlimited widths and complex geometries.

“These solutions can actually be very cost-effective, efficient, and provide a whole new way of working that otherwise is quite prohibitive using normal techniques,” University College London computer science researcher and study co-author Vijay Pawar told The Daily Beast.

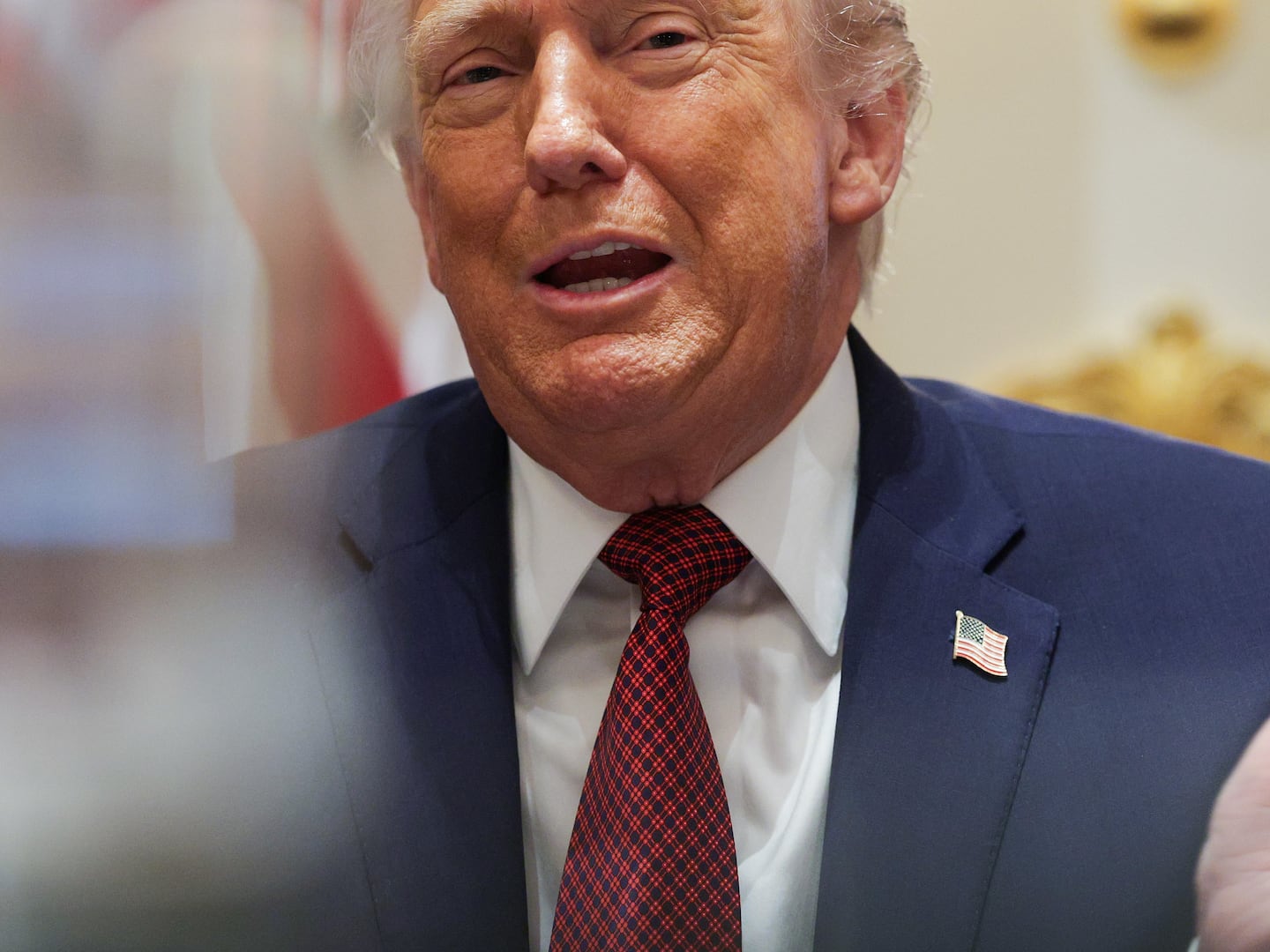

The novel building material designed specifically for the new construction drones.

University College London, Department of Computer Science, London. Dr Vijay M. Pawar & Robert Stuart-Smith, Autonomous Manufacturing LabBut creating the first flying and 3D-printing robots came with a slew of challenges. The researchers had to design a system that could deposit material and remain stable in flight. Additionally, the robot would have to remain light enough to take flight even while carrying the printing material; building materials are purposely heavy so that structures stay sturdy.

To bypass the weight issue, the researchers used rapidly hardening polyurethane foam and then developed a lightweight version of cement for the robots to use. “Basically, we had to engineer a brand-new material,” Stuart-Smith said.

The team of engineers tested the drones out over several trials, each of which would be relevant to future applications in construction. First, they programmed one drone to build an almost seven-foot cylindrical tower of foam (a second drone scanned the progress after each layer to chart the robot’s progress and verify that material was being deposited as planned). Then, a pair of drones built a seven-inch woven cylinder using the cement-like material (the end result looked like a cross between a wicker basket and drip sandcastle.) The researchers also simulated builds of cylinders and domes with groups of three and more drones, using beams of light instead of physical materials and taking time-lapse images of the results.

It took the drones 300 seconds per layer to construct the cement-like cylinder, or 2.3 hours minutes in total. Stuart-Smith said that the robots will get faster and more efficient as the technology is refined, particularly when testing begins outdoors and researchers can use larger, more powerful drones.

Rahul Panat, a mechanical engineering researcher at Carnegie Mellon University who was not involved in the study, said that the research represented steps forward for both 3D printing and robotics. “[Aerial robots] would remove roadblocks to many applications of 3D printing and go beyond the limits of current technologies,” he told The Daily Beast.

Before a fleet of drones can be contracted to build the next skyscraper, however, researchers need to improve both the manufacturing and robotics sides of the technology, Panat added. Standards-setting must play a role, too, since companies that build swarms of drones code them in dozens of different programming languages.

With continued development, swarms of drones “could provide an alternative means to support housing and vital infrastructure in remote locations” or places made inaccessible due to natural disasters and the effects of global warming, the authors wrote in the study.

But they could also play a role even closer to home: Construction that takes place just one or two stories aboveground currently requires human crews and can put these workers in dangerous positions. Drones, on the other hand, would still allow for human supervision without the potential for fatal accidents, Stuart-Smith said.

All-in-all, a future construction site may no longer be dotted by men and women in hardhats and steel-toed boots baking under the hot sun to get a building done in piecemeal fashion. It might instead just be a swarm of drones printing the whole thing out in one fell swoop.