3D printing technology has come a long way in the past few years—and one of its most promising applications is in medicine. Not only have we seen it be used to create artificial bones and tendons, but it’s even capable of making skin that can feel (which is a lot less creepy than it sounds).

Now a multi-university team of scientists have taken it a step further and created a 3D printer that goes inside the human body. That’s the idea behind a new study published Thursday in the journal Science into a new method that allows researchers to use ultrasonic waves to “print” structures through layers of biomaterials like skin, muscle, and bone.

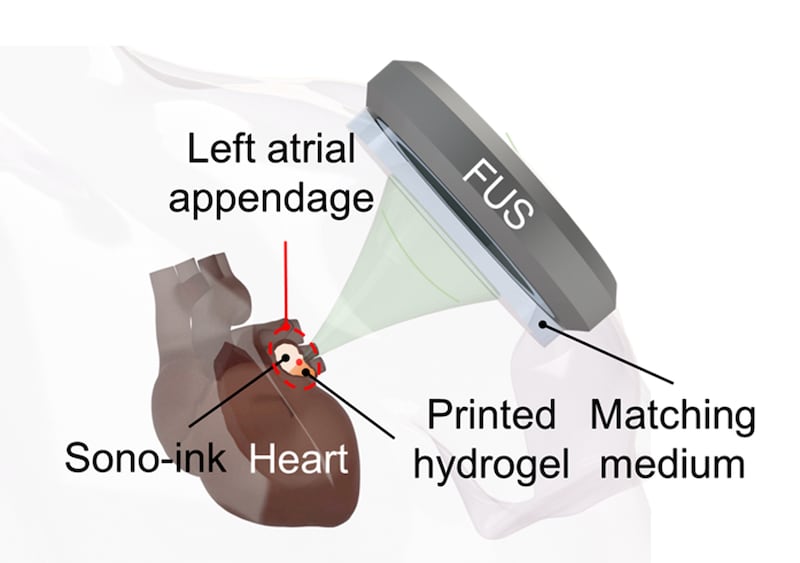

The technique is known as Deep-Penetrating Acoustic Volumetric Printing (DAVP), and relies on a specially designed substance called “sono-ink” to create different structures within the human body.

“DAVP works by directing focused ultrasound waves at a fluid medium containing sono-inks,” Junjie Yao, a biomedical engineer at Duke University and co-author of the paper, told The Daily Beast. “These inks are formulated to respond to ultrasound, allowing them to solidify in specific patterns as the ultrasound wave scans through them.”

Illustration showing the minimally invasive left atrial appendage closure by delivering and solidifying sono-inks in the entire atrial appendage appendage volume.

Xiao KuangMost 3D printing techniques that you’re likely familiar with relies on light-based approaches. As the device creates layers of plastic in the shape of whatever you’re printing, a UV light shines on the object to help solidify and harden it.

This is great if you’re creating things like construction material or even robots. However, it’s less ideal if you’re trying to do things inside of the human body. Despite this, there’s a lot of potential for internal 3D printers to do things like repair broken bones and internal wounds.

“For instance, it could be used to print biocompatible structures directly inside the body, such as scaffolds for tissue regeneration or sustained drug delivery systems,” Yao explained. “This method could significantly enhance treatments for various medical conditions by enabling precise interventions without the need for invasive surgery, thereby reducing patient recovery time and improving outcomes."

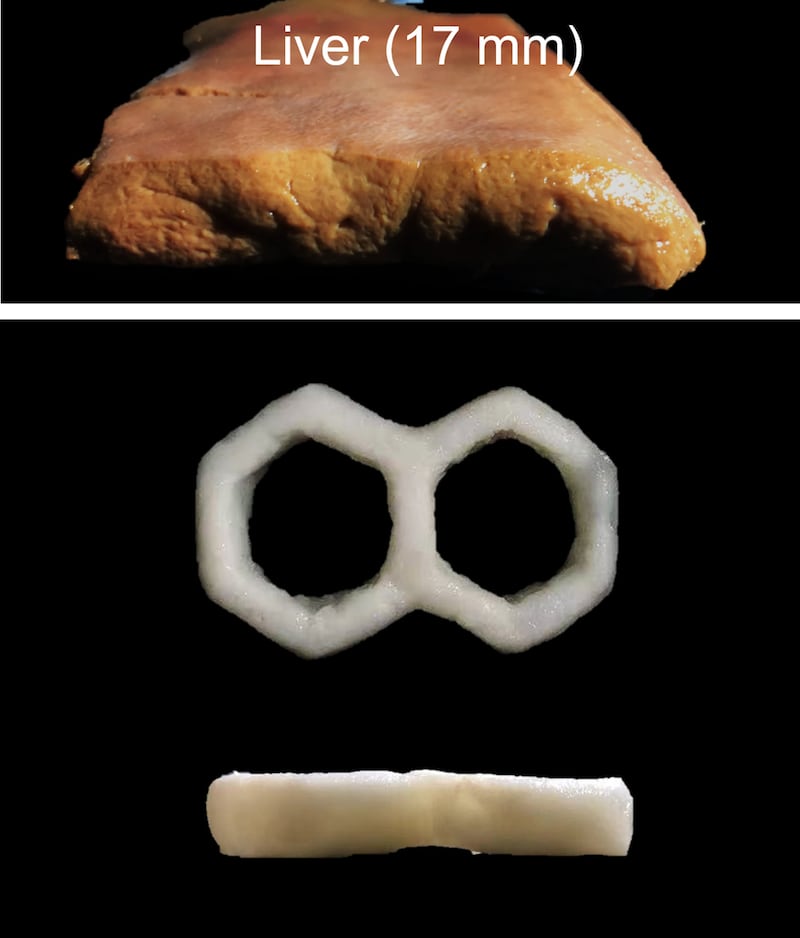

A simple 2D honeycomb was printed through a 17-thick porcine liver on a 2.05-MHz FUS using a PEGDA-based sono-ink.

Qiangzhou RongThe process utilizes a tiny catheter that’s inserted into the body to deliver the sono-ink. As the sono-ink is injected, an ultrasonic device on the outside morphs the material into the shape needed to repair the bone, patch up torn tissue, or even inject life-saving medicine.

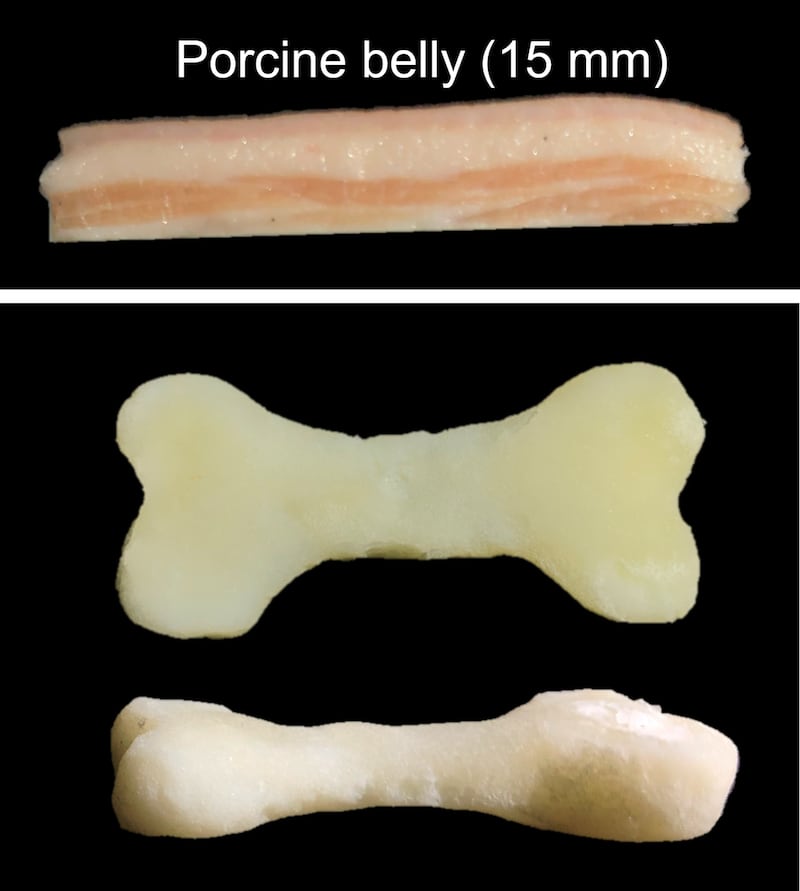

In experiments, the technique was capable of 3D printing complex shapes such as letters and spirals through layers of biomaterial such as a pig’s heart, belly fat, and kidney. It was also shown to be able to effectively deliver a chemotherapy treatment into a pig’s liver.

“It offers greater precision and control, allowing for the creation of intricate structures at depths not previously achievable,” Yao said.

A 2D vessel network (82 mm by 68 mm by 1 mm) was printed on a 3.41-MHz FUS using a PEGDA-based sono-ink.

Qiangzhou RongHowever, the technique has yet to be used on any human patients. More research is needed before it can move to human trials and, potentially, rolled out to hospitals and medical facilities all over the world.

The team behind DAVP say that they hope to refine and optimize the printing technology, while also “exploring new materials for sono-inks to expand the capabilities and applications of acoustic volumetric printing,” Yao explained. Eventually, they plan on collaborating with clinical researchers in order to see how the method works in actual medical settings.

Yao added, “We're excited about the potential impact of this work and look forward to seeing its real-world applications in the near future.”

A 3D bone model was printed through 15-thick porcine belly tissue on a 2.05-MHz FUS using a PEGDA-based sono-ink.

Qiangzhou Rong